Vision Inspection

With the introduction of smart cameras in the 1980’s, vision inspection equipment has reached widespread use in the food, packaging and pharmaceutical industries as a means to inspect print, label and package integrity. Our easy-to-use machine vision systems perform accurate label and package quality inspections on plastic containers, glass bottles, jars, screw or snap-on caps, flat packages, cartons and pill packs. Requiring minimal line space and modifications, automated vision inspection systems are easy to install and can operate at speeds up to 2,000 packager per minute.

Vision Inspection Applications

Label Check Inspection

Label inspection systems use a combination of graphical and print identification tools, including label ID verification, to spot a mislabeled product and remove it from the production line. In addition, our vision systems can verify that labels are correctly applied to the packaging surface, absent of any wrinkles, flagged edges or tear to ensure perfect product presentation.

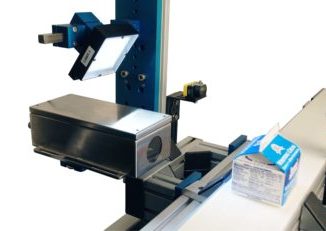

Code Reading & Inspection

Code reading systems provide automated in-line inspection of alphanumeric, 1D and 2D datamatrix, and QR codes on product packaging surfaces and labels. Using optical character recognition and verification, our smart cameras can also ensure the accuracy of different codes, including dot matrix fonts.

Serialization/Track & Trace Inspection

Our track and trace systems provide turn key, automated solutions for marking, verifying and recording of serialized information. Serialization is most often seen in the pharmaceutical industry to comply with regulations. Vision systems, combined with aggregation and software tools, can be used for any industry including cosmetics and high value product.

Cap and Fill Level Inspection

Vision systems can also be used to inspect, cap presence/cocked cap, as well as tamper band integrity. Our robust software allows us to teach the vision system to identify good product and packaging with proper cap and seal placement, and visually identify subtle differences in position to detect and reject instances of packaging failure.

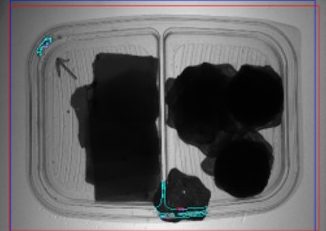

Seal & Channel Leaker Inspection

If a package has a clear and consistent container, and the product provides enough contrast, we can use vision systems to detect contents extending into a seal or channel of package. Seal & channel leaker inspection ensure seals are not compromised which can lead to premature product spoilage and poor product aesthetics.