Fill Level Inspection

Quality Control For Filling Systems

Fill Level Inspection is just that, measuring the level of product in a package, to detect over and under fills. Depending on the package and product characteristics, quality control of packaging material and filling inspection can be achieved with x-ray or vision technology. With cantilevered wash-down rated construction and tool-less changeover, our inspection systems can easily operate in harsh environments to inspect steel, aluminum, plastic and glass containers .

Fill Level Inspection Applications

X-ray Inspection

Our X-ray sensor is a non-contact sensor used to measure the product fill level in steel, aluminum, glass, plastic and paper containers. An x-ray tube energized at high voltage is used to produce a low energy x-ray beam. This x-ray beam is focused to look through the container in the expected fill level region.

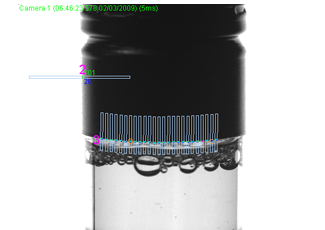

Vision Inspection

In addition to cap presence and positioning, our vision systems are also capable of performing fill level inspection in order to ensure that all packages have been properly filled. Unnecessary product giveaway is a source of lost profit, and under-filled products can result in trouble from government regulators.