Palletizing Equipment

Robotic & Gantry Palletizers

Palletizing typically falls into two different categories: conventional and robotic. Conventional palletizers, often called Gantry, are built for speed and involve forming pallet pattern layers and lifting either the row or pallet to achieve stacked product. Our robotic palletizers are built for flexibility and utilize a robot that is capable of autonomously palletizing product into patterns using a gripper or end-of-arm tool. Being that the robot is programmable via a PLC, a robotic palletizer can handle multiple pallets at a time even with different pallet configurations. The robot can also be programmed to de-palletize using vision systems.

Palletizing Equipment Applications

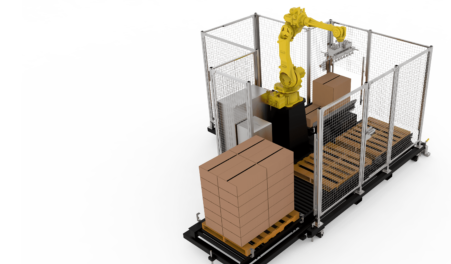

Robotic Palletizer Systems

Our robotic palletizers are built for flexibility and utilise a robot that is capable of autonomously palletizing product into patterns using a gripper or end-of-arm tool. Being that the robot is programmable via a PLC, a robotic palletizer can handle multiple pallets at a time even with different pallet configurations. The robot can also be programmed to depalletize using vision systems.

Gantry Palletizer Systems

Our gantry palletizers are built for speed and involve forming pallet pattern layers and lifting either the row or pallet to achieve stacked product. With quick change over, speeds up to 50 cases per minute, our gantry palletizers offer an efficient and compact solution that will allow your product to be prepared for shipping quickly.