In-line X-ray Inspection

X-ray Inspection Systems

Industrial X-ray systems for the food and pharmaceutical sectors are built to work in tough environments. They are fully automatic, run at high line speeds and offer exceptional ferrous, non-ferrous and stainless-steel detection, even for products packaged in foil or metalized film. Glass, mineral stone, high density plastics and rubbers can also be detected. Unlike traditional inspection systems, x-ray technology is not affected by changes in product temperature or moisture, ensuring minimum false rejects.

In-line X-ray Inspection Applications

Packaged Product Inspection

X-ray inspection systems for packaged products offer maximum foreign body contamination detection sensitivity at high throughputs for a diverse range of food and pharmaceutical applications in various types of retail packaging. Typical packaged applications include foil and plastic containers, cartons/boxes, foil pouches, bags and sacks, trays, tubes, sachets, flow-wraps, PET bottles and blister packs.

Pumped Product Inspection

Pipe X-ray systems are specifically designed to inspect pumped product at any stage before final processing and packaging. Due to product being pumped through a narrow x-ray manifold, pipe x-ray systems deliver outstanding contamination detection of foreign bodies such as glass,metal, mineral stone, calcified bone, high density plastic and rubber compounds. Typical fresh meat products inspected include but not are limited to trim meat, ground meat, whole muscle, rendered meat, and collagen. Beyond fresh meat, typical food applications typically include sauces, jams, chocolate and dairy spreads, as well as products that cannot be sieved - for example, textured fruit purées and yogurts containing fruit chunks.

Unpackaged and Bulk Product Inspection

Bulk food x-ray inspection systems operate in industries such as meat, fish & seafood, fruits & vegetables, snacks, confectionery and pet food etc. Utilized in a wide variety of bulk-flow (loose) food products to improve quality control before they are packaged, (or added as ingredients to finished products), bulk x-ray systems applications include nuts, grains and pulses, extruded snacks, dried fruits, cereals, vegetables, frozen seafood, minced meat and sweets.

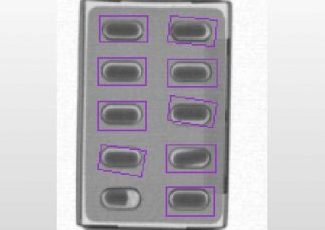

Blister Pack Inspection

Using object count tools, x-ray systems can count the pills within a blister package and are used to detect either under-filled blister packs, missing pills or partial pills, or overfilled blister packs. Often times in these applications, x-rays are used instead of checkweighers due to the overall weight variance of the package masking the ability to checkweigh efficiently and detect one pill.

Medical Device & Kit Inspection

Using object count and zone tools, x-ray systems can inspect medical device packages and general kits to detect missing components or devices, and also over and under filled components. Often times in these applications, x-rays are used instead of checkweighers due to the overall weight variance of the package masking the ability to checkweigh efficiently and detect one missing component

Canned Food Inspection

X-ray inspection systems provide superior contamination detection for manufacturers producing food, beverages and pet food products packaged in a wide variety of metal cans. Inspection solutions are available for all shapes and sizes of cans, plus numerous tinned applications. Typical applications are baby food, ready meals, fish and seafood, meat, fruit and vegetables, pet food and beverages. In addition to providing unsurpassed contamination detection, x-ray inspection systems provide quality assurance by performing a variety of product and presentation checks. X-ray inspection systems can simultaneously perform a wide range of in-line checks such as monitoring fill levels, measuring headspace and detecting container defects, whilst ensuring reliable contamination detection at high line speeds.

Glass Container Inspection

Glass container x-ray inspection systems are relied upon by food, beverage and pharmaceutical manufacturers worldwide to ensure product safety and integrity. X-ray inspection systems are ideal for detecting contaminants in glass jars and bottles containing a broad range of products such as condiments and sauces, fish and seafood, fruit and vegetables, infant feeding products, ready meals, meat, poultry and dairy as well as beverages and medicines. In addition to providing contamination detection, glass container x-ray inspection systems simultaneously can perform a range of quality control check including over/under fill level inspection and detecting presence and secure positioning of lids.